The Cold Grind Uprising

by Josh Fields, COMPAK AMERICA, LLC

Undoubtedly, a high degree of obsession is required for engineering better coffee grinders in the pursuit of making coffee better. Re-engineering, tweaking, and testing with the objective of product improvement and optimization is the only road to the elusive grinding utopia. As with all great journeys the path is windy and long, and progress is realized in years, not days or months.

As one continues to peel the proverbial onion, it becomes apparent that these damaging by-products can be narrowed to one principal condition, which is the generation of HEAT. I believe that the reapplication of heat to a product that had already been carefully crafted using heat (roasted coffee beans) is critical to avoid. Minimizing the undesirable by-product of elevated temperatures resulting from the grinding process is a precise dance that plays an outsized role in the final characteristics of how the brewed coffee tastes.

Opportunities to reduce heat during the grinder-bean flow process include but are not limited to: internal air flow, burr speed, friction reduction, and materials used. Below are some of the controls that I have found to help ensure a cool grind:

- Increased Internal Air Flow: By placing strategically located air vents, along with a dual fan system which draws internal, warm air out the upper section of the unit near the motor, and a second fan drawing cool air up through the bottom of the grinder, temperature stability is greatly enhanced.

- Low Burr RPM: Slow burr rotation speed should be precisely configured to optimize quick production while minimizing heat generation. Gear reduction systems allow for SLOW cold rotation commonly found on conical burr grinders as well as some large flat burr models found on the market. This has played a huge part in striking this critical balance of performance and low temperature stability.

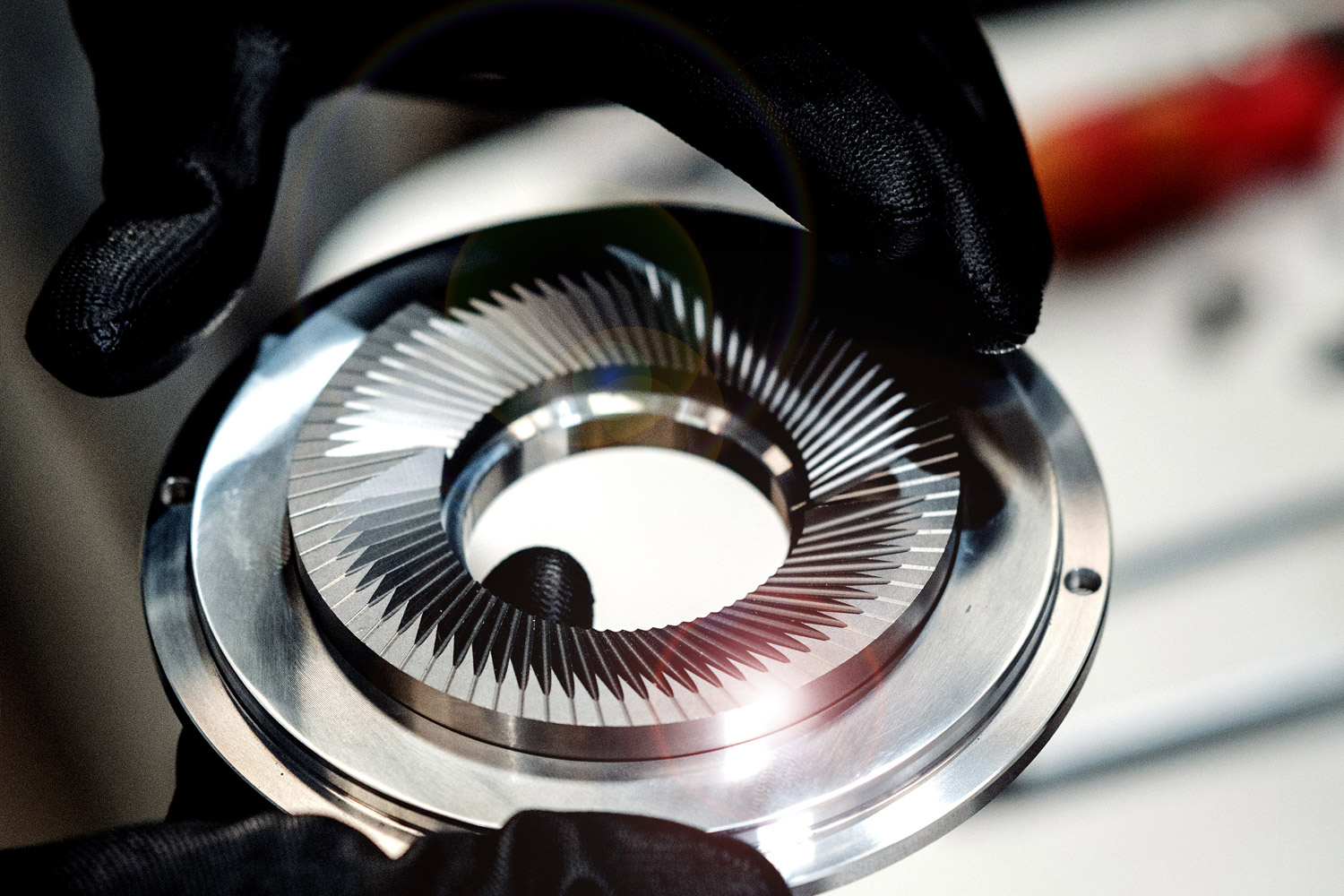

- Large Flat or Conical Burrs: Using large diameter, deeply cut flat or conical burrs increases ground coffee rate per revolution, and fewer revolutions means reduced heat and friction.

- Burr Material Optimization: Selected burr materials such as K-110/D2 steel for burrs are a low friction, high strength cold work steel. Commonly used in the pharmaceutical, medical, and oil drilling industries, such materials are optimal for temperature control and stability for high friction applications.

The end result of the exhaustive task of purging heat generating factors is wondrous temperature stability. After all, there is nothing cooler than experiencing a coffee’s flavor the way your roaster carefully crafted it to taste.

The Coffee Technicians Guild

"The Cold Grind Uprising"